Hoonved ST 53E Bruksanvisning

Hoonved

Diskmaskin

ST 53E

Läs gratis den bruksanvisning för Hoonved ST 53E (20 sidor) i kategorin Diskmaskin. Guiden har ansetts hjälpsam av 12 personer och har ett genomsnittsbetyg på 4.4 stjärnor baserat på 6.5 recensioner. Har du en fråga om Hoonved ST 53E eller vill du ställa frågor till andra användare av produkten? Ställ en fråga

Sida 1/20

ST 43 E

ST 48 E

ST 53 E

ST 60 E

DP 35 E

DP 40 E

DP 45 E

DP 50 E

Instructions for user

Ed. 10/2012

Via Ugo Foscolo, 1

21040 Venegono Superiore

Varese (Italy)

www.hoonved.com

info@hoonved.com

DICHIARAZIONE DI CONFORMITÀ CE I

DECLARATION OF CONFORMITY CE GB

CE DECLARACION DE CONFORMIDAD

E

DECLARATION DE CONFORMITÉ CE

FR

KONFORMITÄTSERKLÄRUNG CE D

CE CONFORMITEITSVERKLARING

NL

CE KONFORMITETSERKLÆRING

DK

Noi dichiariamo sotto la nostra esclusiva responsabilità che il prodotto:

The undersigned hereby declares under full responsability that the following product:

Declaramos bajo nuestra responsabilidad que el produeto:

Nous soussignées attestons sous notre entière responsabilité que le produit suivant:

Die unterzeichnete Fa. erklärt unter eigener Verantwortung, dass folgende Produkte:

Ondergetekende firma verklaart dat de:

Hermed erklæres at f

Ø

lgende produkter:

LAVASTOVIGLIE - DISHWASHER – LAVAVAJILLAS - LAVE-VASSEILLE - GESCHIRRSPÜLER -

VAATWASMACHINE - TALLERKENOPVASKEMASKINE -UNDERBANKDISKMASKIN

ST 43 E...,ST 48 E...,ST 53 E...,ST 60 E...,ST 43 DE...,ST 48 DE...,ST 53 DE...,ST 60 DE...

DP 35 E...,DP40 E...,DP45 E...,DP 50 E...,DP 35 DE...,DP40 DE...,DP45 DE...,DP 50 DE...,

al quale questa dichiarazione si riferisce, è conforme alle seguenti norme:

for which this declaration refers to in accordance to the following standards:

al que se refiere asta declaracciones de conformidad a las siguientes normas:

auquel se référe cette dèclaration,est conforme aux normes suivantes:

auf welche sich diese Erklärung bezieht, folgendem Standard entsprechen:

waarop deze verklaring betrekking heeft, volgens de standaard:

som er omfattet af denne erklæring, overholder f

Ø

lgende standarder:

EN 60335-1, EN 60335-2-58, EN 61000-3-2, EN 61000-3-3, EN 55014-1, EN 55014-2

in base a quanto previsto dalle Direttive CEE:

on the basis of what is foreseen by the Directives CEE:

en base a lo previsto en la directiva CEE:

selon ce qui est prevu par les Directives CEE:

aufgrund der vorgesehenen Richtlinien:

gebaseerd op de CE-richtlijnen:

iht. EU-direktiv:

2006/95/CE (LVD) - 200 /108/CE (EMC)4

Decliniamo ogni responsabilità per sinistri a persone o a cose derivanti da manomissione da parte di terzi o da carenza di manutenzione o

riparazione.

We decline any responsability for injuries or damage derived from machine misuse, abuse by others or improper machine maintenance

or repairs.

Declinamos toda responsabilidad por sinostros a personas por la incorrecta manipulacion por parte de tercero e la carencia de

mantenimjento o reparaciòn.

Nous déclinons toute responsabilité pour sinistres à personnes ou à objetqui derivent de l'intervention de la part de tiers non specialistes

ou de carences de manutentionou reparation.

Wir lehnen jegliche Verantwortung für Schäden an Personen oder Dingen ab, die auf fehlerhaftes Eingreifen Dritter oder auf mängelhafte

Wartung oder Reparation zurückzuführen sind.

Wij zijn op geen enkele manier verantwoordelijk voor schade aan personen of materrialen welke voortvloeien uit onoordeelkundig

gebruik, reparatie dan onderhoud aan de machines door derden.

Vi frasiger os ethvert ansvar for skader opstàet son f

Ø

lge af fejlagtig anvendelse af maskinen, misbrug, eller utilstrækkeligt vedligehold

eller reparation.

_____ _____ 23/12/2009

(Data emissione)

(Date of issue)

(Fecha de emisiòn)

(Date d'emission)

(Ausgabedatum)

(D.D)

(Udstedelsesdato)

Giuseppe RIENZI

DELEGATO ALLA SICUREZZA DEL PRODOTTO

__________________________________________

(Nome e firma o timbratura equivalente della persona autorizzata)

(Name signature or equivalent of authorized representative)

(Nombre y firma o equivalente de la persona autorizada)

(Nom et signature ou cachet de la personne autorisée)

(Name und Stempel der rechtskräftigen Person)

(Naam handtekening of equivalent van de rechtsgeldige vertegenwoordiging)

(Underskrift)

ST E.doc

3

cod. 37590

ST 43 E - DP 35 E

ST 48 E - DP 40 E

ST 53 E - DP 45 E

ST 60 E - DP 50 E

DISHWASHING MACHINE

The illustrations concerning these instructions are on the inside of the back cover

Mod.

5

La ditta costruttrice si riserva il diritto di apportare

modiche che si renderanno utili ai propri prodotti

senza comprometterne le caratteristiche essenziali.

The manufacturer reserves the right to modify the

products whenever necessary, without affecting their

main features.

Le constructeur se réserve le droit de modier ses

produits sans en compromettre les caractéristiques

essentielles.

Der Hersteller behält sich das Recht vor , seine Pro-

dukte abzüandern , falls es notwendig sei , ohne die

haupteigenschaften des Gerät zu wechseln.

La Firma constructora se reserva el derecho de modi-

car sus productos sin comprometer las características

esenciales.

A empresa construtora se reserva o direito de fazer

modicações que se renderem necessárias aos pró-

prios produtos sem o comprometimento das carac-

terísticas essenciais.

ITA AVVERTENZA

Prima di procedere all'installazione, alla messa in funzione, alla regolazione e alle operazioni di manutenzione della lavastoviglie

Mod. ST/DP E, leggere attentamente il presente manuale.

In caso di guasto o cattivo funzionamento della macchina rivolgersi esclusivamente ad un centro tecnico autorizzato o diretta-

mente alla ditta HOONVED.

°

ENG IMPORTANT

Become thoroughly familiar with the contents of this manual before installing, setting up, adjusting and servicing dishwasher

machine Mod. ST/DP E.

Only contact an authorized technical center or HOONVED in the event of breakdowns or faulty machine operation.

FRA IMPORTANT

Lisez attentivement cette notice avant la mise en place, la mise en service, le réglage et les opérations d’entretien de la machine

lave-vaisselle Mod ST/DP E.

En cas de panne franche ou de dysfonctionnement de la machine, adressez-vous exclusivement à un service technique agréé

ou directement à la société HOONVED.

DEU HINWEIS

Bevor man den Geschirrspüler Mod. ST/DP E installiert, in Betrieb nimmt, einstellt oder Wartungsarbeiten daran vornimmt, ist

dieses Handbuch aufmerksam durchzulesen.

Bei Betriebsstörungen der Maschine wenden Sie sich bitte ausschließlich an ein autorisiertes Kundendienst-Zentrum oder direkt

an Firma HOONVED.

ESP ATENCION

Antes de realizar la instalación, la puesta en marcha, los ajustes y las operaciones de mantenimiento de la máquina lavavasos

Mod. ST/DP E, lea atentamente este manual.

En caso de avería o de mal funcionamiento se dirija exclusivamente a un centro técnico autorizado o directamente a la empresa

HOONVED.

POR ADVERTÊNCIA

Antes de proceder a instalação, a colocação em funcionamento, a regularização e as operações de manutenção da Lava

louças Mod . ST / DP E, ler atentamente o presente manual. Em caso de avaria ou mal funcionamento da máquina procurar

exclusivamente um centro técnico autorizado ou directamente a empresa HOONVED.

7

INDICE - INDEX - ÍNDICE

RAEE.................................................................... pag. 4

Avvertenza. ......................................................... pag. 5

Important

Important

Hinweis

Advertencias

Advertência

Dimensioni d'ingombro. .................................... pag. 6

Overall dimensions pag. 6 ...............................................

Dimensions d'encombrement pag. 6 ...............................

Platzbedarfmasse ................................................. Seite. 6

Dimensiones máximas pág. 6 .........................................

Dimensões pág. 6............................................................

Dati tecnici. ......................................................... pag. 7

Technical data pag. 7.......................................................

Données techniques pag. 7 .............................................

Technischen daten................................................ Seite 7

Datos técnicos pág. 7 ......................................................

Dados técnicos pág. 7 .....................................................

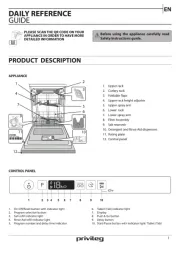

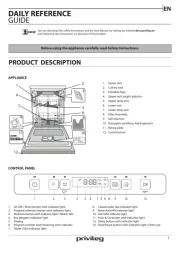

Descrizione comandi........................................... pag. 8

Decription of the controls pag. 8 .......................................

Description des commandes pag. 8 .................................

Beschreibung der Bedienvorrichtungen pag. 8 ................

Descripción de los mandos pag. 8 ...................................

Descrição dos comandos pag. 8 ......................................

ITALIANO. ........................................................ Pagina 9

ENGLISH. ......................................................... Page 18

FRANÇAIS. ...................................................... Page 27

DEUTSCH. ....................................................... Seite 36

ESPAÑOL. ....................................................... Página 45

PORTUGUÊS. .................................................. Pág. 54

8

DIMENSIONI DI INGOMBRO - OVERALL DIMENSIONS - DIMENSIONS D'ENCOMBREMENT

PLATZBEDARFSMASSE - DIMENSIÓNES - DIMENSõES

ST 43 E - DP 35 E 430 530 694 860 280

ST 48 E - DP 40 E 480 530 694 860 280

ST 53 E - DP 45 E 530 620 751 964 270

ST 60 E - DP 50 E 600 620 816 1030 330

Modello Model A B C D E

10

CYCLE

II III

START

CHECK

A

B

D

C

E

10

CRUSCOTTO COMANDI - CONTROL PANE PANNEAU DES COMMANDESL -

SCHALTBLENDE - PANEL DE MANDOS - PAINEL DE COMANDOS

Fig. 1

LEYENDA

Q1) Interruptor ON/OFF

S4) Botón regeneración (solo para mod. "D")

LRCK) Lámpara led CHECK

LTV) Lámpara led temperatura agua tina

LC1) Lámpara led ciclo CORTO

LC2) Lámpara led ciclo MEDIO

LC3) Lámpara led ciclo LARGO

S9) Botón selecciòn CICLO

S3) Botón de Arranque CICLO (START)

P3) Temperatura cuba (display)

P2) Temperatura boiler (display)

LEGENDA

Q1) Interruttore ON/OFF

S4) Tasto Rigenera (solo su modelli "D")

LRCK) Lampada led CHECK

LTV) Lampada led temperatura vasca

LC1) Lampada led ciclo CORTO

LC2) Lampada led ciclo MEDIO

LC3) Lampada led ciclo LUNGO

S9) Tasto selezione CICLO

S3) Tasto AVVIO CICLO (START)

P3) Display temperatura vasca

P2) Display temperatura boiler

LEGEND

Q1) Line button ON/OFF

S4) Regeneration button ( only for models "D")

LRCK) CHECK led light

LTV) Tank temperature led light

LC1) SHORT cycle led light

LC2) MEDIUM cycle led light

LC3) LONG cycle led light

S9) CYCLE selection button

S3) START CYCLE button

P3) Tank temperature (display)

P2) Boiler temperature (display)

LEGENDE

Q1) Bouton de ligne ON/OFF

S4) Bouton de régénération

(seulement pour "D")

LRCK) Lampe led de CHECK

LTV) Lampe led de temperature de la cuve

LC1) Lampe led cycle COURT

LC2) Lampe led cycle MOYEN

LC3) Lampe led cycle LONG

S9) Bouton de Sélection CYCLE

S3) Bouton de Démarrage CYCLE (START)

P3) Display temperature cuve

P2) Display temperature boiler

LEGENDAS

Q1) Tecla ON/OFF

S4) Botão regenerador (Só nos modelos “D”)

LRCK) Lâmpada Led CHECK

LTV) Lâmpada Led temper. do tanque

LC1) Lâmpada Led ciclo CURTO

LC2) Lâmpada Led ciclo MÉDIO

LC3) Lâmpada Led ciclo LONGO

S9) Botão de selecção de ciclo

S3) Botão início ciclo (START)

P3) Temperatura agua tina (display)

P2) Temperatura hervidor (display)

ZEICHENERKLÄRUNG

Q1) Schalter Ein-/Aus

S4) Regenerierungs-Taste (nur bei "D")

LRCK) Led Leuchte Regenerierung CHECK

Alarm

LTV) Led Leuchte tanktemperature erreich

LC1) Led Leuchte KURZER zyklus

LC2) Led Leuchte NORMALER zyklus

LC3) Led Leuchte LANGER zyklus

S9) Wahltaste ZYKLUS

S3) Taste ZYKLUS STARTEN

P3) Tankstemperature (display)

P2) Boilerstemperature(display)

C

C C

III III

P3 P2 Q1 S4 LRCK LTV S9 S3

LC1LC2LC3

START

CHECK

23

PARTICULAR RECOMMENDATIONS

FOR THE OPERATOR

- Do not operate the machine without having become fully

familiar with the contents of this manual and without having

acquired a comprehensive knowledge of the specic tech-

niques and machine controls.

- Check that the area in which the machine is to be installed is

compatible with the dimensions of the machine itself before

installing this latter.

- If this machine is a ”built in” type , pay attention that the

housing and the furnishings nearby are suitable ones ,

i.e. they have not to suffer from exposure to steam that

may come out from the machine during its functioning

and especially during the opening of the door at each

washing cycle.

- Only use lifting and handling means that are suited to the

weight of the machine when this must be installed or removed

either completely or in part.

- Never allow unauthorized or unqualied personnel to start,

adjust, operate or repair the machine. Always refer to this

manual for the necessary operations.

- The mechanical parts and electrical/electronic components

situated inside the machine are protected by entirely closed

panels.

- Always ensure that the main switch has been set to the

“OFF” position before cleaning and/or servicing the machine.

This will disconnect the power source during the operator’s

intervention.

- The electrical powering system must be equipped with an

automatic release system prior to the main machine switch

and with a suitable grounding system that complies with all

the requisites established by industrial provisions for the

prevention of accidents.

- Always disconnect the power source if work must be carried

out on the main switch or in its vicinity.

- All inspections and maintenance operations requiring remo-

val of the safety guards are carried out under the complete

responsibility of the users.

These operations should therefore only be carried out by

specialized and authorized technical personnel.

- Make sure that none of the accident preventing safety de-

vices (barriers, guards, casings, microswitches, etc.) have

been tampered with and that they are all perfectly functional

before operating. These devices should be repaired if this is

not the case.

- Never remove the safety devices.

- To prevent personal risks, only use power tools that are

correctly connected to the grounding tap and that conform

to the national safety regulations.

- Never ever tamper with the electrical system or with any

other mechanism.

- Never ever use the hands or unsuitable instruments to locate

leaks from pipes. Air, uids under pressure or irritants could

cause serious damage to both persons and/or property.

- Never use the hands instead of adequate tools when operating

the machine.

- Never use the hands or other objects to stop moving parts.

- PAY THE UTMOST ATTENTION TO THE DATA PLATES

AFFIXED TO THE MACHINE WHENEVER WORKING ON

THIS OR IN THEIR NEAR VICINITY.

- The user is obliged to keep all the data plates and stickers

in a legible condition.

- Never climb on to the door or on to the top of the machine.

- It is essential for the user to replace all data plates and

stickers that may have deteriorated for any reason or that

are not clearly visible, ordering new ones from the Spares

Service.

- Contact the person in charge of maintenance in the event of

malfunctions or damage to the machine components without

proceeding with further repairs.

- It is absolutely forbidden for anyone to use the machine for

purposes other than those explicitly established and docu-

mented. The machine must always be used in the ways, times

and places dictated by common sense and the laws in force

in each country, even when there are no specic provisions

to govern the sector in the particular country of use.

- The manufacturer declines all responsibility for accidents

or damage to either persons or property as may arise

following failure to comply with either the relative safety

provisions or the instructions herein.

- These instructions, together with the provisions gover-

ning machine installation and electrical connections form

an integral part of the Accident Preventing Industrial

regulations in force in each individual country.

- THESE SAFETY PROVISIONS INTEGRATE AND DO NOT

SUBSTITUTE THE SAFETY PROVISIONS LOCALLY IN

FORCE.

- NEVER ever make hurried or inaccurate repairs that

could jeopardize the correct operation of the machine.

- ALWAYS ASK FOR HELP FROM SPECIALIZED PERSON-

NEL IN CASE OF DOUBT.

- ANY TAMPERING BY THE USER RELIEVES THE MA-

NUFACTURER FROM ALL LIABILITY, THE USER BEING

IN THIS CASE SOLELY RESPONSIBLE TOWARDS THE

COMPETENT ACCIDENT PREVENTION AUTHORITIES.

- The machine must not be used by people (chidren inclu-

ded) with reduced physical, sensory or mental abilities,

with lack of experience or acquaintance, unless they

could have a supervision or instruction concerning

the use of the machine, through the intermediation of a

person responsible for their safety.

- It is forbidden to clean the machine with water jets.

ENGLISH

Traslation from the original instructions

25

ENGLISH

Part 2: For the operator

2.1 WASHING PHASES ST/DP E

2.1.a Switching on and Preparing the machine

(Fig.1/9)

To switch on the machine,press and hold the power switch

( ) into the position button for a few seconds, then Q1 ON

release.

The LED indicating the last cycle selected will become

CONSTANTLY LIT (LC1, LC2, LC3 or LC1+LC2+LC3)

, as will the CHECK LED .

IMPORTANT

On rst switching on, LED LC2 will light up.

The boiler, and then the tank, will start to ll automatically.

Once the water level has been reached, the heating

elements will switch in, rst in the boiler, then in the tank.

Once the water in the tank reaches the correct tempera-

ture, the tank temperature LED ( ) will go ON. LTV

The thermometers P3 and reect the tank and boiler P2

values of temperature.

WASHING OPERATION

If not equipped with an automatic dosing system, pour

into the tank a quantity of detergent suitable for the volu

me and hardness of the water. For quantities, refer to the

specic instructions for the detergent in use.

ATTENTION

When items to be washed are encrusted with burnt

on matter, or a long time has passed between use

and washing, it is essential to carry out a pre-was

soak using a suitable softening agent.

The use of hand-washing products is to be avoided

as they could produce foam inside the machine.

IPlace the basket of items to be washed inside the ma-

chine, having rst removed any solid waste.

2.1.b Selecting a Cycle

The duration of the washing cycle can be chosen from

4 different lengths of time, to be selected using the

“CYCLE” button.

Each time the button is pressed, the LEDs “CYCLE”

(LC1, LC2,LC3 or LC1+LC2+LC3), will light up or go out

in sequence as shown in the following table:

LC 1 : = 90 sec. SHORT CYCLE

LC 2: = 120 sec. MEDIUM CYCLE

LC 3: = 180 sec. LONG CYCLE

LC 1+LC2+LC3: = 8 1/2 min. INTENSIVE CYCLE

2.1.c STARTING UP THE WASHING CYCLE

IMPORTANT

The selection of MANUAL orAUTOMATIC start to be

made with machine in stand-by mode

STARTING the MANUAL WASHING CYCLE

To start the washing cycle, press and hold the START (S3)

button for a few seconds, then release.

Throughout the washing cycle the LED(s) for the selected

cycle or will FLASH.(LC1, LC2 LC3 or LC1+LC2+LC3)

ATTENTION

We recommend that you top up the detergent used up

by washing grease or dispersed during rinsing every 4-5

complete cycles.

The use of the machine ensures rinsing at the ideal tem-

perature for hygienic purposes every time;

Indeed, if the temperature is not sufcient the wash will

be automatically prolonged so as to ensure the necessary

conditions of optimum rinsing at 85°C.

The waiting time required to attain optimum temperature

can extend to a maximum of .8 minutes

While this is taking place, the LED will FLASH CHECK

RAPIDLY until the end of the cycle. To reset the ashing,

switch the machine off and back on using the power

switch ( ) .Q1

STARTINGUPTHEWASH. CYCLEAUTOMATICALLY

To start up the cycle AUTOMATICALLY (by opening and

closing the door), you will need to change the cycle start

up mode. Press and hold the “ ” button until theCYCLE

pre-selected cycle LED remains BLINKING LIT

(approx. 10 sec.) and the washing cycle will then start up

AUTOMATICALLY when the door is closed.

The functioning of the led (CONTINUOUS or BLINKING)

depends on the chosen type of functioning(MAN. or AUT)

2.1.d Interrupting the cycle

1) It is possible to interrupt the washing cycle momentarily

by opening the door, this is an EMERGENCY measure:

the cycle LEDs (LC1, LC2,LC3 or or LC1+LC2+LC3) will

start to FLASH, alternating with the LED CHECK .

On closing the door, operations will resume from the point

in which they stopped.

2) The cycle can also be interrupted by SWITCHING the

machine’s power switch ( ) to the position.Q1 OFF

3) On switching the machine back on, the LED indicating

the last cycle selected will light up.

At the end of the washing cycle, take out the basket

and shake it gently so as to remove the last drops

left on the washed items.

Allow items to dry and remove them from the basket with

clean hands.

Store all items on hygienic and completely stable surfaces.

2.1.e Manual Draining

It is possible to drain the water from the tank at any time

during the day, according to the waste accumulated.

To carry out this operation, proceed as follows:

- SWITCH the machine’s power switch ( ) to the Q1 OFF

position and release the overow, allowing all the water

to drain from the tank;

- Remove the tank lters (22/23) and clean;

C

I II III

LC1LC2LC3

CHECK

26

ENGLISH

Part 2: For the operator

2.1.e.1Manual draining for mach. with drainage pump

For machines tted with a drainage pump it is possible

to empty the tank by carrying out the manual draining

cycle, during which only the drainage pump remains

active.

IMPORTANT

This cycle can only be carried out by leaving the ma-

chine SWITCHED ON with the tank full of water and the

door OPEN.

Having released the overow, press and hold the

START (S3) button until the LED LC2 and CHECK

together) begins to FLASH, and then release the

START (S3) button;

The DRAINAGE CYCLE will begin.

IMPORTANT

By pressing the START ST ( ) button or switching

the power switch ( ) to OFF, you can interrupt the Q1

drainage cycle before the preset time is up;

to restart the interrupted cycle, press START (S3)

again.

When the LED lights up CONSTANTLY,LC2

the drainage cycle is nished.

At the end of the cycle, restore the lters (22/23) and the

overow (21) to their respective positions.

2.1.f Self-washing and draining

At the end of the washing operations SWITCH OFF the

machine pressing the switch ( )Q1

After having unlocked the overow pipe, close the door

of tank access , press push button START (S3) (about

5 sec.)

The cycle Self-washing and draining will start ; Led LC1

and will light, while led is FIXED ON, with LC3 CHECK

draining pump ON (for the machines equipped with).

The end of the described phase is indicated by the switch-

ing OFF of the Led ,CHECK

2.1.g Cold rinsing (optional)

With machine ON (switch line is ON ), tank full of Q1

water and door closed (LC1 or LC2 or LC3 and CHECK

= FIXED ON)

keep pressed regeneration button ( ) to make the cold S4

rinsing of the crockeries for all the wished time.”

2.1.h Switching off at the end of the day

At the end of the working day SWITCH OFF the ma-

chine by pressing the power switch ( ) into the Q1

OFF position.

Switch off the mains switch feeding the machine

and close the water supply taps.

For any repairs, contact only assistance centres au-

thorised by the manufacturer.

Warnings during the operation

1) Ensure that the washing temperature remains at

approx. 55-60°C;

2) Avoid immersing bare hands in the detergent-lled

water; if this should happen, rinse immediately and

thoroughly with running water;

3) Use only anti-foaming detergents, specics for use in

industrial machines;

4) Deactivate the machine in case of break-down or

malfunction.

For any repairs, contact only assistance centres autho-

rised by the manufacturer, and insist on the use of

original parts.

5) In no case should you change the the original for-

mulations without rst consulting an authorised

assistance centre;

6) When the machine is operating, do not open the door

too rapidly.

7) Wash tank water should be changed at least twice a

day or according to daily wash requirements.

Failure to follow the above warnings may compromise

the safety of the washing machine.

Useful advice for better washibg results

Any unsatisfactory results from washing can be seen

when traces of dirt are left on dishes or other items; any

water marks may be caused by insufcient rinsing.

In this case, ensure that the rinsing nozzles (27) are

clean and that there is pressure in the water system.

If there are traces of waste, ensure that:

- The lters (22/23) are clean;

- the water temperature is around 55-60°C;

- items are correctly positioned in the basket;

- the washing/rinsing nozzles are clean (26/27);

- the arms (24/25) rotate freely.

2.1.i RESIN REGENERATION OPERATION

(for model D only)

We recommend that you carry out regeneration when all

work is nished.

First of all, ensure that there is coarse cooking salt in the

salt container, and proceed as follows:

1. unscrew the salt container plug and pour in 1 Kg of

coarse salt.

2.Screw the plug down tight, to ensure that the container

is completely sealed.

On reaching the set number of cycles, the LED CHECK

will ash;

this indicates that it is time to carry out regeneration.

The signal that the set number of cycles has been reached

can only be deactivated by starting the regeneration cycle

(regenerate button ). ( )S4

REGENERATION OPERATIONS

With the machine SWITCHED OFF (the power switch

( ) in the position), and the tank EMPTY (release Q1 OFF

the overow) and the door CLOSED, press and hold the

regenerate button (Fig. 1/ 9), until the LED ( )S4 CHECK

FLASHES.

The REGENERATION CYCLE will begin, and the

CHECK LED will ash continuously.

The machine will now automatically carry out all the ne-

cessary operations for a MAXIMUM of 20 mins, during

which the machine cannot be used.

ATTENTION

Opening the door during the cycle will stop the regenera-

tion cycle; the LED will start to ash RAPIDLY; CHECK

on closing the door the cycle will resume from where it

was stopped.

CI II III

LC1LC2LC3

CHECK

27

ENGLISH

Part 2: For the operator

When the LED switched OFF, the CHECK

regeneration cycle is nished.

The machine is now ready for use again.

ATTENTION

Programming of cycles for the start-up of regeneration

should be carried out by authorised technicians only (see

Part 3: Reserved for technicians, paragraph 3.2 Setting

cycles for REGENERATION PROMPT).

2.2 CLEANING (Fig. 10)

2.2.a General information

Strict compliance with the maintenance instructions in this

section will keep your machine in a good working condition

and will notably reduce the need for repairs.

ATTENTION

If any machine component becomes faulty, FIRST CHECK

that all the instructions given in the previous paragraphs

have been complied with during use.

Repairs must be carried out immediately, as soon as the

fault occurs. This will prevent the trouble from becoming

worse and damaging other parts.

ATTENTION

Daily operations to carry out when work has ended, with

the machine OFF , the main circuit-breaker disconnected,

the water cocks off and the washing tub empty.

1. Thoroughly clean the inside parts of the machine.

2. Remove the suction protection (23).

3. Remove the lter (22) from the bottom of the machine

by releasing the overow (21).

4. Wash the lters under running water and t them cor-

rectly back in their housings.

ATTENTION

Frequently check and clean the spraying units, removing

them from their housings and eliminating any dirt and

fouling. The frequency with which this operation must be

carried out depends on the quantity of dirt or on the unsa-

tisfactory washing results. Never use corrosive products

like sodium hypochlorite (bleach) or hydrochloric acid, wire

wool or steel brushes to clean either the inside or outside

parts of the machine.

2.3. PREVENTION MAINTENANCE (Fig. 10)

The preventive maintenance operations must be carried

out with the machine OFF, the main circuit-breaker di-

sconnected, the water delivery cocks off and the washing

tub empty.

2.3.a Checking and cleaning the spray arms and

nozzles (Fig. 10)

Periodically check to make sure that the lower washing

arm and rinsing arm (24/25) and their relative nozzles are

not clogged (26/27).

Cleaning the lower/upper unit

1. Unscrew the ring nut and lift the arm (24/25).

2. Wash the washing and rinsing arm.

If the nozzles (27) are clogged, unscrew them to de-

mount and clean, taking care to prevent the shape of

the nozzle from being deformed. After cleaning, t the

nozzles exactly back in their original positions.

3. Remount all parts by complying with the above in-

structions in reverse.

2.4 DESCALING

Where hard water is present lime scale deposits will for

in the machine and on dishes, which must, for reasons

of hygiene, be removed by descaling.

Advice on operation procedures and frequency for this

treatment are generally given by the detergent supplier,

who can provide suitable products.

In order to avoid damaging the machine, do not

exceed recommended doses, follow the detergent

producer’s directions scrupulously and, having

nished operations, rinse thoroughly.

2.5 TEMPORARY STOPPAGE

If the machine is to be left inactive for a period of some

weeks, it is advisable beforehand to load the tank and

run a few empty cycles with clean water then drain, so

as to avoid the formation of unpleasant odours.

If necessary, repeat the process several times until the

water is still clean after washing.

If the stoppage is to be very long, it is advisable to

drain the water from the boiler and from the electric

pump.

2.6 DEMOLITION and DISPOSAL

When the machine is to be scrapped, drain the water

from the tank and from the boiler, as indicated in the

points above, and disconnect the machine from the

water and electricity supply networks, then dispose of

the components according to current regulations, re

specting national and local ecological and environmetal

legislation, and taking care to separate the parts as

follows:

- metallic parts: body work, surfaces, panels, lters;

- electrical parts: motors, remote switches, micro-

switches, cabling;

- plastic parts: connectors, baskets;

- rubber parts: tubes, couplings

2.7 SCHEDULED MAINTENANCE

It is advisable to subject the machine to scheduled

maintenance every 6 months.

The producer declines all responsibility for any

printing errors contained in this booklet.

The instructions, drawings, tables and everything else

in this manual are of a condential technical nature.

For this reason, none of the information may be either

completely or partially duplicated or disclosed to

third parties without prior written authorization from

HOONVED which is the sole proprietor and which

reserves the right to make any modications as may

be considered necessary without advance warning.

28

ENGLISH

Part 2: For the operator

SUMMARY TABLE of CYCLE LED CHECK SIGNALS

MACHINE STATUS CYCLE LED CHECK

Machine OFF OFF

Machine on line but STAND/BY ON CONSTANT

CYCLE: washing, pause, rinsing ON CONSTANT

ALARM: lack of heating RAPID flashing

ALARM: door open RAPID flashing

Manual drain RAPID flashing

Regeneration cycle SLOW flashing

*REGENERATION ALARM SLOW flashing

* Can only be stopped by starting the regeneration cycle, or if it has not been

programmed at all.

Produktspecifikationer

| Varumärke: | Hoonved |

| Kategori: | Diskmaskin |

| Modell: | ST 53E |

Behöver du hjälp?

Om du behöver hjälp med Hoonved ST 53E ställ en fråga nedan och andra användare kommer att svara dig

Diskmaskin Hoonved Manualer

7 Mars 2025

31 December 2025

6 September 2024

4 September 2024

4 September 2024

4 September 2024

3 September 2024

2 September 2024

2 September 2024

1 September 2024

Diskmaskin Manualer

- Cylinda

- Kunft

- Kubo

- Profilo

- Elis And Elsa

- Tisira

- Respekta

- Emilia

- Rhima

- Oranier

- Proline

- KitchenAid

- Exquisit

- Point

- Elektra Bregenz

Nyaste Diskmaskin Manualer

21 Augusti 2025

21 Augusti 2025

21 Augusti 2025

21 Augusti 2025

21 Augusti 2025

21 Augusti 2025

21 Augusti 2025

20 Augusti 2025

20 Augusti 2025

20 Augusti 2025