Servend Flomatic Bruksanvisning

Läs gratis den bruksanvisning för Servend Flomatic (8 sidor) i kategorin kylskåp. Guiden har ansetts hjälpsam av 34 personer och har ett genomsnittsbetyg på 3.5 stjärnor baserat på 17.5 recensioner. Har du en fråga om Servend Flomatic eller vill du ställa frågor till andra användare av produkten? Ställ en fråga

Sida 1/8

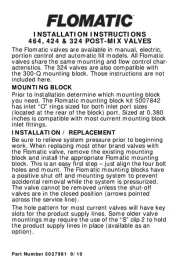

Part Number 5027981 8/10

INSTALLATION INSTRUCTIONS

464, 424 & 324 POST-MIX VALVES

The Flomatic valves are available in manual, electric,

portion control and automatic fill models. All Flomatic

valves share the same mounting and flow control char-

acteristics. The 324 valves are also compatible with

the 300-Q mounting block. Those instructions are not

included here.

MOUNTING BLOCK

Prior to installation determine which mounting block

you need. The Flomatic mounting block kit 5007842

has inlet “O” rings sized for both inlet port sizes

(located at the rear of the block) port. Sized at 0.380

inches is compatible with most current mounting block

inlet fittings.

INSTALLATION / REPLACEMENT

Be sure to relieve system pressure prior to beginning

work. When replacing most other brand valves with

the Flomatic valve, remove the existing mounting

block and install the appropriate Flomatic mounting

block. This is an easy first step – just align the four bolt

holes and mount. The Flomatic mounting blocks have

a positive shut off and mounting system to prevent

accidental removal while the system is pressurized.

The valve cannot be removed unless the shut-off

valves are in the closed position (arrows pointed

across the service line).

The hole pattern for most current valves will have key

slots for the product supply lines. Some older valve

mountings may require the use of the “S” clip 2 to hold

the product supply lines in place (available as an

option).

Produktspecifikationer

| Varumärke: | Servend |

| Kategori: | kylskåp |

| Modell: | Flomatic |

Behöver du hjälp?

Om du behöver hjälp med Servend Flomatic ställ en fråga nedan och andra användare kommer att svara dig

kylskåp Servend Manualer

22 Augusti 2025

kylskåp Manualer

- Smeg

- Whirlpool

- Manta

- FAR

- Enofrigo

- Tomado

- Korting

- Sandstrøm

- OK

- Parmco

- Signature

- Pitsos

- Milectric

- ProfiCook

- Royal Catering

Nyaste kylskåp Manualer

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

21 Oktober 2025

21 Oktober 2025

20 Oktober 2025

20 Oktober 2025