Drayton Twinzone PBTE66 Bruksanvisning

Drayton

ej kategoriserat

Twinzone PBTE66

Läs gratis den bruksanvisning för Drayton Twinzone PBTE66 (2 sidor) i kategorin ej kategoriserat. Guiden har ansetts hjälpsam av 13 personer och har ett genomsnittsbetyg på 4.4 stjärnor baserat på 7 recensioner. Har du en fråga om Drayton Twinzone PBTE66 eller vill du ställa frågor till andra användare av produkten? Ställ en fråga

Sida 1/2

ZONE

VALVE PACK

WITH

LWC 1

WIRING

CENTRE

CONTENTS

Programmer

Zone V

alve Heating

Zone Valve

Hot Water

Room

Thermostat

Cylinder

Thermostat

LWC 1 Wiring

Centre

Heating Control Pack

with

Switchmaster, Lifestyle or Tempus Programmer

INSTALLATION

AND

WIRING GUIDE

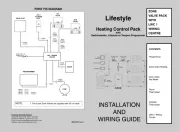

FIRST FIX DIAGRAM

LWC 1 WIRING

CENTRE

PROGRAMMER

BOILER

PUMP

ROOM STAT

HTS 3

CYLINDER

STAT

3 CORE

+ EARTH

2 CORE

2 CORE

+ EARTH

2 CORE

+ EARTH

MAINS 230V. AV

FUSED 3A

NOTE: 1. The 2-port Zone Valves are supplied with 30" of cable

DHW

VALVE

090-667 Iss C

28mm

5 CORE

+ EARTH

22mm

4 CORE

+ EARTH

28mm

5 CORE

+ EARTH

22mm

4 CORE

+ EARTH

4 CORE

SM 400 LP 112

SM 600 LP 241

SM 805 LP 522 Tempus 6

SM 905 LP 722 Tempus 7

Lifestyle

Wiring Centre

Programmer

Cylinder

Thermostat

Boiler

Hot Water Valve Heating Valve

Pump

Room

Thermostat

B A

B A

HTG

VALVE

Invensys Controls Europe

Customer Service Tel: 0845 130 5522

Technical Helpline Tel: 0845 130 7722

Email: customer.care@invensyscontrols.com

Website: www.draytoncontrols.co.uk

Produktspecifikationer

| Varumärke: | Drayton |

| Kategori: | ej kategoriserat |

| Modell: | Twinzone PBTE66 |

Behöver du hjälp?

Om du behöver hjälp med Drayton Twinzone PBTE66 ställ en fråga nedan och andra användare kommer att svara dig

ej kategoriserat Drayton Manualer

21 September 2025

5 Augusti 2025

4 Augusti 2025

ej kategoriserat Manualer

- Mueller

- Philips

- Panasonic

- Lelit

- InLine

- Bender

- DK2 Power

- AXIL

- Homedics

- Tognana

- Mount-It!

- Pigtronix

- Rigol

- Geuther

- SilentiumPC

Nyaste ej kategoriserat Manualer

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025

23 Oktober 2025